OSHA has issued a new regional emphasis program for its Region VII states (Kansas, Iowa, Missouri and Nebraska) that is targeting industries considered to be in the Top 50 for creating worker health hazards. Called, “Top 50 Workplace – Health Hazard,” some of the other OSHA regions have similar emphasis programs, or more targeted programs. Region VII didn’t have a mechanism to inspect for health hazards, so they created this one.

Effective and Enforcement Dates

It is effective October 1, 2021 through September 30, 2026. Enforcement begins January 4, 2022.

What is This About?

This regional emphasis program is related to industrial hygiene. Industrial hygiene deals with worker occupational health and tests the exposures workers have to potential health hazards. Besides protecting workers from safety injuries, OSHA’s goal is to protect workers from health hazards too. Many health hazards are longer term issues that cannot be found by just looking at a company’s injury/illness data.

Exposures to certain substances may not cause health issues and cancer for a number of years. For example, health issues from asbestos exposure may not arise for 15-50 years after exposure, formaldehyde 2-15 years, benzene 1-10 years, hexavalent chromium 20 years and nickel 13-24 years.

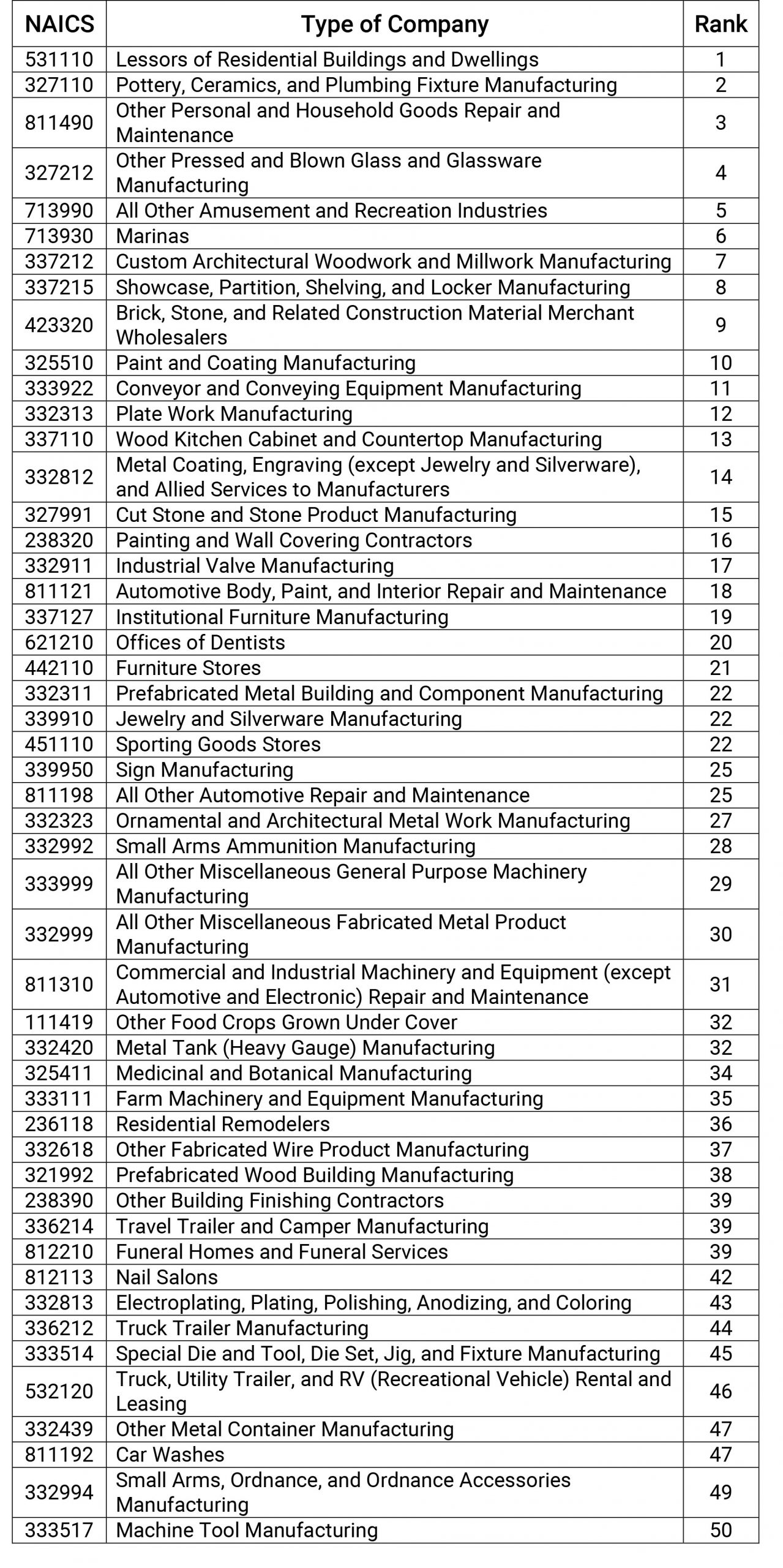

OSHA looked at inspection data from the past 3 years and ranked types of companies by the number of serious violations. They narrowed that list to the Top 50 by NAICS code. From there, they’re putting all the companies that fall within that list into a random picker to develop their first inspection list. All of the companies on that list will be inspected before a new list is generated. If all the companies on the list are not inspected within 3 years, then they’ll carry over to the new list. OSHA will generate a new target list every 3 years at a minimum.

What Will Be Inspected?

By knowing what OSHA will be looking for, you’ll have an idea of what you need to do and the procedures to have in place in order to be ready. Inspectors will ask to see your company’s:

- Exposure monitoring* program;

- Exposure monitoring records;

- OSHA 300 logs to identify threshold hearing shifts, skin disorders, respiratory conditions, poisonings and other illnesses;

- Safety and health programs for ventilation, occupational noise exposure, nonionizing radiation, hazardous materials from Subpart H, PPE, permit-required confined spaces, medical services and first aid, toxic and hazardous substances from Subpart Z and Hazcom; and,

- Your programs for temporary employees. OSHA sees temps as more vulnerable to these types of hazards. And then,

- After the records review, OSHA will conduct a comprehensive walk around of your facility and will be looking for areas where they can conduct occupational exposure sampling to run the tests themselves. That testing will occur as soon as possible. This includes wipe sampling, full-shift and short term monitoring and area sampling. Note: If OSHA shows up for this type of inspection, make sure you do side-by-side sampling with them so that if there are any discrepancies, you’ll be able to point them out.

*Exposure monitoring includes sampling for your employees’ exposure to various health hazards found in your facility. This could be chemicals and substances such as asbestos, heavy metals, and formaldehyde, solvents and paints, hazardous dusts, welding fumes, noise, vibration, temperature, ventilation and particulates.

Remember that there is a number of OSHA emphasis programs already set in place. If your company is the target of one of them they can happen any time OSHA is already onsite for something else. In the directive for this health hazard emphasis, they mention that if you fall under multiple emphasis areas, they’ll stack them and do them all at once in one comprehensive inspection. In Region VII, there’s already a regional noise and respiratory hazards emphasis program. Also in this region there’s a powered industrial truck emphasis so just having a forklift onsite could start the ball rolling on an inspection.

OSHA’s Goals – The Inspections’ Report Card

Knowing OSHA’s goals with these inspections can give you additional insight into what their inspectors will be looking for. Each regional office is required to file a report on their efforts with this emphasis, and in it, they’ll be looking to prove their worth on these efforts, and how their staff helped improve overall workplace health. Some of the data goals include:

- Total number of health hazards abated;

- Total number of overexposures identified;

- Total number of personal air monitoring samples conducted (full shift, short-term, area samples);

- Total number of wipe samples taken;

- Total number of noise samples conducted;

- Total number of workers removed from health hazards;

- Total number of workers found overexposed to each substance found in 1910.1000-1910.1029; and,

- Total number of safety hazards abated/workers removed from safety hazards (that they found at the same time they were there doing the health inspection).

The Top 50

This is the list of the Top 50 NAICS code industries who will be inspected.

What’s Next?

Is your company on this list and what do you need to do in order to be ready if your name is drawn?

iSi can help you get ready with program development, exposure monitoring plans and strategies, onsite exposure monitoring and onsite representation during the inspection. Learn more about industrial hygiene here, or contact us today!

Is Your Company on the List?

We can help with the needed IH monitoring plan, onsite sampling and other assistance. Contact us today!

Contributing:

Curtis Leiker, CSP

Certified Safety Professional | ISO 45001 and 14001 Lead Auditor

Curtis Leiker, CSP is a project manager at iSi Environmental. Besides assisting companies with ISO 14001 and 45001 implementation, Curtis manages environmental and safety programs, reporting and compliance issues for aviation, general industry and agricultural facilities. He’s able to see the big picture, but focus on the details and enjoys working to solve EHS issues.