Grade D Breathing Air: What Requirements Do I Have to Meet for My Breathing Air System?

Compressed air, either through a fixed or a portable system, can be used to supply air to employees as they perform tasks that could not be done using an air purifying respirator.

Supplied air respirators are respirators that supply the user with breathing air from a source independent of the ambient atmosphere.

First we’ll take a look at breathing air and then we’ll cover what its OSHA requirements are.

What Operations Use Supplied Breathing Air?

Supplied breathing air can be used across all industries for many different functions throughout the facility. Some of the most common include:

- Confined Space Entry

- Sand/Media Blasting Operations

- Working in Paint Booths

- Welding

What Are the Components of a Breathing Air System?

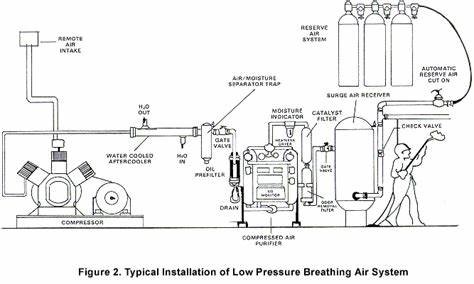

A simple breathing air system has four basic components.

Air Source

The air source can be from a fixed or portable compressor. This compressor can be either electric, gas or diesel powered. Another source can be from bottled or tanked air. The air source should be sized to provide a minimum of 4 cubic feet per minute (CFM), but depending on the work being done, workers may require up to 15 CFM. Typical systems operate around 10 to 12 CFM. Pay special attention to the intake area of the compressor to be sure that no gasses or vapors can be drawn into the system as they will be passed down to the employee.

Filtration

The filtration used is very important. The filtration system should be able to remove water, oil and particles, and many use a charcoal bed to remove odors and tastes. Remember to make sure the filtration system can supply the required CFM. Carbon monoxide (CO) is a special danger if the air source is not an oilless compressor and a CO monitor with alarm is then required. This alarm needs to be able to be heard by everyone connected to the air source at their point of use.

Air Distribution

The filtered air then needs to be set to the proper pressure required by the specific respirator so a regulator will be needed to drop the air pressure and not overpressure the employee’s mask. Employees are able to connect to a breathing air system via quick connect couplings, OSHA requires these couplings to be unique to the breathing air system. This ensures that employees are unable to connect a respirator to a non-breathing air system (shop air). It is also a requirement that the hose the employee uses is a maximum of 300 feet.

Respirator

The selected respirator can be of several varieties such as pressure demand or continuous flow, tight fitting face piece or loose-fitting hoods or helmets. These choices need to be made prior to the set up of the system as they can affect the design of the system. For example, if you are planning to use a continuous flow system a bottle supplied air source will not last very long.

What are OSHA’s Requirements for a Breathing Air System?

Breathing Air Gases Testing

The OSHA standard requires the employer provide employees using atmosphere-supplying respirators with breathing gases of high purity. To this end, OSHA has incorporated the ANSI/Compressed Gas Association Commodity Specification for Air, G-7.1 to include testing to meet the following:

- Oxygen content percentage by volume: Between 19.5% and 23.5%

- Hydrocarbon (oil and particulate): maximum of 5 milligrams per cubic meter of air

- Carbon monoxide: maximum of 10 parts per million by volume

- Carbon dioxide: maximum of 1000 parts per million by volume

- Lack of noticeable odor

This breathing air gases are also commonly referred to as Grade D breathing air. There are other grades of breathing air available that differ in oxygen content, hydrocarbons and water content that are used by fire departments and other SCBA wearers, but Grade D breathing air is the standard for industry.

While OSHA does not require breathing testing to be done on any interval, the industry standard for this testing is to be done annually for each distribution point.

Written Respiratory Protection Plan

Any company requiring employees to use respiratory protection must have a written Respiratory Protection Program that meets all the requirements of 29 CFR 1910.134.

Medical Evaluations

OSHA first requires the respirator user to be medically cleared to use a respirator. The doctor will need to know that the employee will be using a supplied air respirator so they can understand the physical requirements of the respirator being used.

Training

OSHA then requires that all respirator users be trained on how to use their respirator, the limitations of that respirator and any procedures such as when the CO alarm goes off what needs to be done.

Fit-Testing

If the respirator selected is a tight fitting facepiece, OSHA requires a fit test to ensure the facepiece provides a proper seal to the users face.

Preventative Maintenance Plan

On a system that has a CO monitor, a preventive maintenance plan needs to be established to perform calibration on the monitor. Most manufacturers require monthly calibration with a certified canister of carbon monoxide gas. Calibration dates should be documented.

Questions? Need Help?

iSi has Grade D breathing air system testing equipment and routinely conducts tests for our clients. We can also help you with the other breathing air system requirements of OSHA. Contact us today!

Need Help?

iSi can help with Grade D breathing air testing, required written plans, training and more!

Compressed air, either through a fixed or a portable system, can be used to supply air to employees as they perform tasks that could not be done using an air purifying respirator.

Supplied air respirators are respirators that supply the user with breathing air from a source independent of the ambient atmosphere.

First we’ll take a look at breathing air components, then we’ll cover its OSHA requirements.

What Operations Use Supplied Breathing Air?

Supplied breathing air can be used across all industries for many different functions throughout the facility. Some of the most common include:

- Confined Space Entry

- Sand/Media Blasting Operations

- Working in Paint Booths

- Welding

What Are the Components of a Breathing Air System?

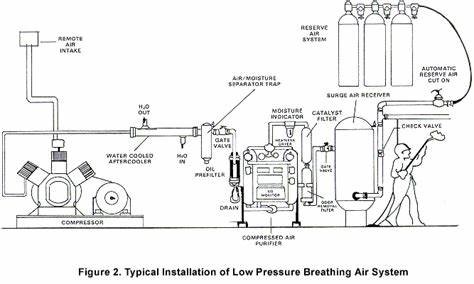

A simple breathing air system has four basic components.

Air Source

The air source can be from a fixed or portable compressor. This compressor can be either electric, gas or diesel powered. Another source can be from bottled or tanked air. The air source should be sized to provide a minimum of 4 cubic feet per minute (CFM), but depending on the work being done, workers may require up to 15 CFM. Typical systems operate around 10 to 12 CFM. Pay special attention to the intake area of the compressor to be sure that no gasses or vapors can be drawn into the system as they will be passed down to the employee.

Filtration

The filtration used is very important. The filtration system should be able to remove water, oil and particles, and many use a charcoal bed to remove odors and tastes. Remember to make sure the filtration system can supply the required CFM. Carbon monoxide (CO) is a special danger if the air source is not an oilless compressor and a CO monitor with alarm is then required. This alarm needs to be able to be heard by everyone connected to the air source at their point of use.

Air Distribution

The filtered air then needs to be set to the proper pressure required by the specific respirator so a regulator will be needed to drop the air pressure and not overpressure the employee’s mask. Employees are able to connect to a breathing air system via quick connect couplings, OSHA requires these couplings to be unique to the breathing air system. This ensures that employees are unable to connect a respirator to a non-breathing air system (shop air). It is also a requirement that the hose the employee uses is a maximum of 300 feet.

Respirator

The selected respirator can be of several varieties such as pressure demand or continuous flow, tight fitting face piece or loose-fitting hoods or helmets. These choices need to be made prior to the set up of the system as they can affect the design of the system. For example, if you are planning to use a continuous flow system a bottle supplied air source will not last very long.

What are OSHA’s Requirements for a Breathing Air System?

Breathing Air Gases Testing

The OSHA standard requires the employer provide employees using atmosphere-supplying respirators with breathing gases of high purity. To this end, OSHA has incorporated the ANSI/Compressed Gas Association Commodity Specification for Air, G-7.1 to include testing to meet the following:

- Oxygen content percentage by volume: Between 19.5% and 23.5%

- Hydrocarbon (oil and particulate): maximum of 5 milligrams per cubic meter of air

- Carbon monoxide: maximum of 10 parts per million by volume

- Carbon dioxide: maximum of 1000 parts per million by volume

- Lack of noticeable odor

This breathing air gases are also commonly referred to as Grade D breathing air. There are other grades of breathing air available that differ in oxygen content, hydrocarbons and water content that are used by fire departments and other SCBA wearers, but Grade D breathing air is the standard for industry.

While OSHA does not require breathing testing to be done on any interval, the industry standard for this testing is to be done annually for each distribution point.

Written Respiratory Protection Plan

Any company requiring employees to use respiratory protection must have a written Respiratory Protection Program that meets all the requirements of 29 CFR 1910.134.

Medical Evaluations

OSHA first requires the respirator user to be medically cleared to use a respirator. The doctor will need to know that the employee will be using a supplied air respirator so they can understand the physical requirements of the respirator being used.

Training

OSHA then requires that all respirator users be trained on how to use their respirator, the limitations of that respirator and any procedures such as when the CO alarm goes off what needs to be done.

Fit-Testing

If the respirator selected is a tight fitting facepiece, OSHA requires a fit test to ensure the facepiece provides a proper seal to the users face.

Preventative Maintenance Plan

On a system that has a CO monitor, a preventive maintenance plan needs to be established to perform calibration on the monitor. Most manufacturers require monthly calibration with a certified canister of carbon monoxide gas. Calibration dates should be documented.

Questions? Need Help?

iSi has Grade D breathing air system testing equipment and routinely conducts tests for our clients. We can also help you with the other breathing air system requirements of OSHA. Contact us today!

Need Help?

iSi can help with Grade D breathing air testing, required written plans, training and more!

Contributing:

Keith Reissig

Industrial Hygienist | Project Manager

Keith brings over 20 years of industrial hygiene and safety experience to iSi and its clients. An industrial hygienist, Keith jokes that he "sucks air for a living." He specializes in workplace exposure testing and sampling strategies, safety compliance, ergonomics and training in a variety of topics in both the industrial hygiene and safety field.

For ongoing snake control, iSi recommended placing glue traps along the inside walls of the building, making sure that the traps are not adjacent to standing pipes. A snake is able to wrap around the pipe and leverage itself off the trap. Also, turning up the heat in the building may increase the capture of snakes on the glue traps because they are not able to hibernate when they are so warm. Building personnel were advised that, if they chose to relocate the snakes, to release them at least two miles from the building during any season but winter. Racers have a home range of 25-50 acres, and would find their way back if not released far enough away.

For ongoing snake control, iSi recommended placing glue traps along the inside walls of the building, making sure that the traps are not adjacent to standing pipes. A snake is able to wrap around the pipe and leverage itself off the trap. Also, turning up the heat in the building may increase the capture of snakes on the glue traps because they are not able to hibernate when they are so warm. Building personnel were advised that, if they chose to relocate the snakes, to release them at least two miles from the building during any season but winter. Racers have a home range of 25-50 acres, and would find their way back if not released far enough away.