If you are a contractor, subcontractor or vendor, it’s likely the number of times you’ve been sent prequalification paperwork or links has increased significantly in the past few years. Standardized prequalification websites such as ISNetworld, Avetta, Veriforce, ComplyWorks, First Verify, COMPASS and others are increasingly being used. These sites are mostly for safety prequalification, but more and more business information has been added to them.

How Does ISNetworld Work?

Programs such as ISNetworld allow companies to turn contractor vetting and risk management over to someone else, putting tracking responsibilities back onto the contractors themselves. The companies who use ISNetworld to manage their contractors are referred to as “Owner Clients.” Owner Clients can use these programs to narrow the field of potential contractors to just the serious ones who have good policies, programs and performance. ISNetworld gives you a grade based on how complete your profile is, if you’ve included all the information that Owner Client wants, how good your safety stats are compared to what the Owner Client’s standards are and how your stats compare to other companies in your NAICS code. Each Owner Client has their own requirements and grading system so you could have an A with one company, a B with another and a C with another. Many times we’ve seen ISNetworld participation and grades are connected to purchasing so you will need to be a member in good standing in order to get paid. To join, there is an annual subscription fee you must pay first, and then you take the time and effort to enter all your company information and programs into the system.

In this article, we’re going to focus on ISNetworld because they are one of the leaders in the safety prequalification industry. Avetta and Veriforce are also amongst the top as well, and they will ask for many of the same things ISNetworld will. At first glance, setup for ISNetworld setup can look like a very daunting task. To help get you prepared, we present the Top 10 items you’ll need to gather for ISNetworld compliance (and just about any other safety prequalification program).

The Top 10 Items You’ll Need to Gather for ISNetworld (and Just About Any Other Safety Prequalification Program)

- General Company Information

You will need to know basic information about your company such as date established, structure, addresses and contacts, special codes and numbers (NAICS, Tax ID, DUNS, etc.), number of employees, financial and project references and more.

- Safety Policies and Procedures

You will be asked a number of questions about your safety policies such as: How is your safety program set up, how is it built and who’s responsible? What’s the management structure and is company leadership involved? Are hourly employees involved and do you have full-time safety personnel? What training do supervisors get? Do you do audits, who does them and how often? Some clients will ask about your safety culture and if you’ve had a third-party survey of your culture. If not, ISNetworld can do one for you.

Also included are questions about safety meetings, training, documentation, observations, stop work policies, hazard reporting, policies for new hires, incident investigation and communication.

- Written Safety Programs

If you’re following OSHA compliance, you should already have written safety programs for the hazards your employees can be exposed to – and at a minimum, the programs OSHA requires you to have. Depending on the services you say you provide in your company profile, ISNetworld and your Owner Client will generate a list of the individual written safety programs that you are required to show. There will be specific elements that you’ll be required to incorporate into your written programs, so it’s likely you’ll need to update your programs.

Be very mindful what your revised program commits your company to. If it’s written in your program that your company will do something, you need to do it. If not, you could expose yourself to fines from OSHA for not following your own plan. ISNetworld will ask you every 3 years to revalidate these programs to ensure they are still current.

If you are a company such as iSi who does many, many different kinds of services, be very careful about all the services you say your company provides. When we first signed up we were only doing asbestos work for one Owner Client, but we put in all the other industrial and consulting services we do. That triggered a huge list of required programs that were needed and many were brand new ones we needed to develop because they were not typical written programs needed by OSHA, or were smaller components of larger programs. We went back and just put in just the asbestos service and it shrunk the list by half. Once we started doing other services for more Owner Clients, we had to add those back onto our profile and any new programs added became more manageable to handle.

- Training Programs

For some of the written programs, you’ll be asked to upload corresponding training documentation from those classes, so you may need to conduct additional training on a variety of topics. Besides OSHA-required training, some Owner Clients will add requirements for additional training. The training always corresponds to the written program for that same topic. Certain trainings require annual uploads of training documentation, and others can have other frequencies as long as 3 years.

Be prepared to answer questions related to what kind of training you provide to new hires and routine employees, how often and how they are documented.

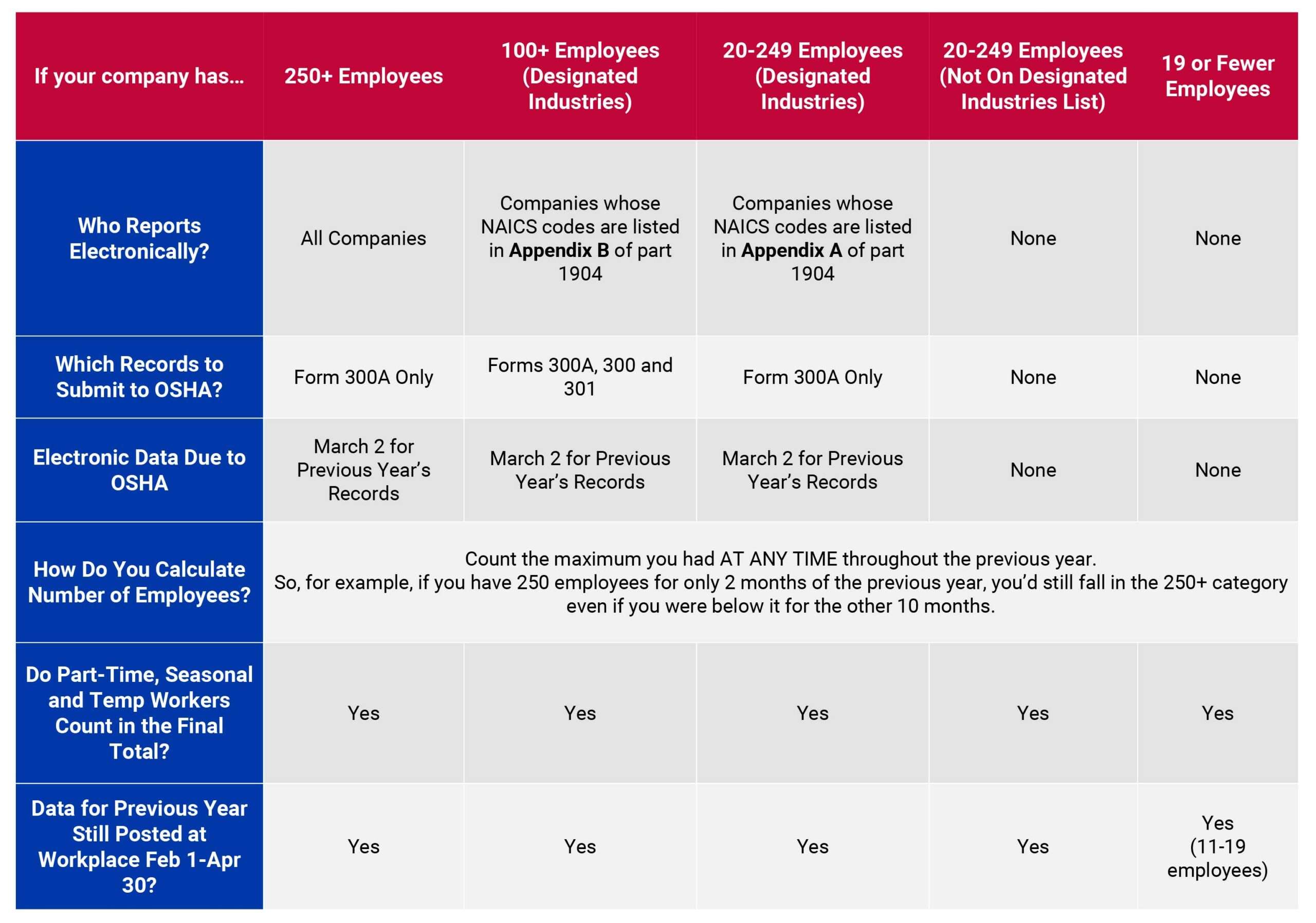

- Regulatory Data

You will need to track OSHA injury and illness data on a quarterly basis. This information is required to be input both quarterly and annually. In ISNetworld you are graded on your 3-year average safety numbers and how they compare to industry standards. Thus, if you have a bad year, your grades may suffer for 3 years.

If you have commercial vehicles, you may need to enter DOT numbers and annual stats for number of drivers, miles driven, number of units, owner operators and violations. You’ll also need to enter in information about your company vehicle/driver programs and policies.

- Insurance

Individual insurance certificates will need to be uploaded for each client, and each will have specific requirements. Be mindful of what the insurance requirements are for each client and know ahead of time what policies you have and what that covers. Sometimes clients will require specialized policies or varying levels of coverage for certain items that can end up costing thousands of dollars if you agree to that. However, sometimes these things can be negotiated down, depending on what you’re going to do onsite. It just depends on the client and the situation.

Check with your insurance company to see if they’re a member of ISNetworld. If so, you can assign them to your account and they can upload certificates and deal with the nuances and negotiations for you. You will also need to enter 3 years of experience modification rate data and upload those documents as well.

- Employee and Contractor Data

Some clients will require you to track the number of hours that you and/or your subcontractors spent on the site each month. These reports are typically required at the beginning of the month and can be required per site location. Among the data you may need to report (depending on client requirements) will be hours spent onsite, number of employees onsite, number of miles driven, number of incidents (accidents, fires, spills), subcontractor hours, subcontractor numbers, subcontractor travel data, etc. Some Owner Clients are required to keep track of this information for Process Safety Management purposes and some like to keep track of contactor activities onsite.

- Human Resources-Type Information

You’ll be asked to input your drug and alcohol policies and procedures. Some owner clients will require you to have individual employees tested for drugs and alcohol through one of their approved vendors who shares the data directly with the program so that they can see if employees are in a green “OK” status or a red status. They may also require background checks for each employee who will come onsite as well. You may also need to provide employee personal information separately to your client to comply with Department of Homeland Security checks as well. Thus, you may need to pull in some of your HR department to help you accomplish some of these requirements and get some answers.

- Other Procedures — Sustainability and Cyber Security

Within the past couple of years we’ve seen questions pop up in ISNetworld and throughout multiple programs about our corporate sustainability and social responsibility programs. One program (not ISNetworld) required us to write a separate written policy statement against human trafficking and a written policy on our stance on child and forced labor. ISNetworld has an extensive cyber security questionnaire to fill out. Several owner clients required us to develop a written cyber security program. So besides HR personnel, you may need to bring in your IT people and anyone responsible for sustainability programs to help answer questions.

- Site-Specific Individual Training Before Going Onsite

More and more clients are requiring individuals to do facility-specific safety orientation training ahead of time before ever stepping onsite. Thus, if you have a specific project that you’re getting ready for, you may need to know exactly who is going to be involved in the project so that you can assign this training to them. This would include subcontractor employees too. Some clients will let you do the training all at once in a group, but more and more are requiring individuals to be given separate logins so that they can complete the training themselves. You may need to eventually to enter specific employees in the system and assign them to training. You will also need to budget time for those employees to take that training. ISNetworld now has the Empower app which allows individual employees to download an app that’s connected to all of their assigned training or other items such as required worker acknowledgements in one place. They can take the training and make acknowledgments through the app rather than giving each one a login and password for online computer access.

A Plan for Getting All the Information Entered and Keeping It Updated

A best practice is to identify a person(s) on your team who’s going to be responsible for managing sites such as ISNetworld. There can be a number of time-sensitive items which need to be completed. Not maintaining them will make your grades drop, hindering your ability to get further work with them or even issue invoices. You may need one organizer who can pull in different subject matter experts when needed.

The initial setup may require the assistance of a number of people in your company, or the help of an outside firm. You may need a combination of compliance personnel and administrative staff to handle the day-to-day management. Please note that if you do involve administrative staff, policy questions and program creation are best completed by someone with a compliance background. You need to be very careful on how you answer the questions and what you commit yourself to. It could make all the difference between an “A” and an “F”.

Keeping your records updated will be important when it’s time to add a new Owner Client who may want you to do the project RIGHT NOW. It will take long enough to get insurance reviewed, employees trained on site-specific requirements. Don’t let missing programs or general training hold your grades down, cost you valuable time or make your Owner Client want to choose someone else.

Other Considerations

ISNetworld automatically uploads any OSHA citations for your clients to see, and these will likely affect your grade. You may also be required to have your own subcontractor management program, that is, a procedure for vetting your own subs.

We’ve found that ISNetworld is one of the most detailed prequalification sites. The silver lining is if you can get through ISNetworld, you have a good head start on some of the others. However, every single site will ask for something new that one of the others didn’t, so don’t get too frustrated. For example, some sites want you to upload your entire safety manual, some require specific procedures such as JSAs, and some will require much more if your employees perform specific tasks that require additional “operator qualifications” for each.

Resources

Make sure you keep your information stored in one central place so that it’s easy to access when you need it because it’s likely there will be information you’ll need to input a number of times.

iSi helps companies get setup in ISNetworld by providing policy and procedure guidance, written programs and training. We also manage ISNetworld day-to-day compliance for companies.

Our sister company SafetyPlans.com has a number of ISNetworld-related program templates that will help you get a good start on developing a new plan if needed.

What can we do to help make the process smoother for you? Contact us today!

Grill outside, away from structures. Make sure your grill is stable on a flat surface so that it can’t be tipped over. Keep the grill clean and wait for it to cool before you clean it. Check for propane leaks on your gas grill, and if you’re using charcoal, wait for the coals to completely cool before you dispose of them. Always dispose coals into a metal container. If the flame goes out on your grill, turn off the grill AND turn off the gas, then wait 5 min. before relighting. If you use a charcoal grill, only use charcoal starter fluid. If the fire starts to go out, don’t add any starter fluid or any other flammable liquids to the fire.

Grill outside, away from structures. Make sure your grill is stable on a flat surface so that it can’t be tipped over. Keep the grill clean and wait for it to cool before you clean it. Check for propane leaks on your gas grill, and if you’re using charcoal, wait for the coals to completely cool before you dispose of them. Always dispose coals into a metal container. If the flame goes out on your grill, turn off the grill AND turn off the gas, then wait 5 min. before relighting. If you use a charcoal grill, only use charcoal starter fluid. If the fire starts to go out, don’t add any starter fluid or any other flammable liquids to the fire. For walk-behind mowers, rotary blades underneath the mower can rotate at 200 mph. Keep your hands and feet away from the blade area when it’s running. Never remove installed safety guards such as directional flaps or shielded discharge outlets or bypass safety shut down devices such as clutch handles or switches that stop the blade as soon as you let go. Mow back and forth along the side of a steep hill, never up and down the slope.

For walk-behind mowers, rotary blades underneath the mower can rotate at 200 mph. Keep your hands and feet away from the blade area when it’s running. Never remove installed safety guards such as directional flaps or shielded discharge outlets or bypass safety shut down devices such as clutch handles or switches that stop the blade as soon as you let go. Mow back and forth along the side of a steep hill, never up and down the slope. to cool. Keep people and pets at least 60 ft. away and stop if you’re approached. Use both hands when operating.

to cool. Keep people and pets at least 60 ft. away and stop if you’re approached. Use both hands when operating. Get familiar with the difference between these plants and how to spot them. Remember, leaves of three, let them be! For rashes use a cold compress, calamine lotion, non-prescription hydrocortisone cream, or an antihistamine to ease itching. You can also use other non-traditional treatments such as wrap dipped in apple cider vinegar. Call your doctor if the rash is near your eyes or covers a large part of your body.

Get familiar with the difference between these plants and how to spot them. Remember, leaves of three, let them be! For rashes use a cold compress, calamine lotion, non-prescription hydrocortisone cream, or an antihistamine to ease itching. You can also use other non-traditional treatments such as wrap dipped in apple cider vinegar. Call your doctor if the rash is near your eyes or covers a large part of your body. Never swim alone, and always supervise children. Open water prevents a number of different hazards that pools don’t. These include limited visibility, depth changes, uneven surfaces, unknown objects that can be stepped on, and currents and undertow. Enter the water feet first to prevent head injury. This includes using water slides. Never dive into water that’s less than 8 ft. deep. Be on the lookout for maintenance issues around the swim area. Be alert of wet floors, sharp edges, broken glass, exposed bolts, broken ladders, broken railings and clear markings of water depth. If you find yourself struggling or accidentally fall in, float to live. Try not to panic as calmness will save you. Lean back and use your arms and legs to keep you afloat with gentle movements. Once you’re calm your breathing is controlled, then call for help or swim to safety. Don’t let your dog swim without supervision. While many dogs know how to swim, some can easily tire out.

Never swim alone, and always supervise children. Open water prevents a number of different hazards that pools don’t. These include limited visibility, depth changes, uneven surfaces, unknown objects that can be stepped on, and currents and undertow. Enter the water feet first to prevent head injury. This includes using water slides. Never dive into water that’s less than 8 ft. deep. Be on the lookout for maintenance issues around the swim area. Be alert of wet floors, sharp edges, broken glass, exposed bolts, broken ladders, broken railings and clear markings of water depth. If you find yourself struggling or accidentally fall in, float to live. Try not to panic as calmness will save you. Lean back and use your arms and legs to keep you afloat with gentle movements. Once you’re calm your breathing is controlled, then call for help or swim to safety. Don’t let your dog swim without supervision. While many dogs know how to swim, some can easily tire out. g and damage your vehicle’s suspension. Check the hitch for the maximum trailer and maximum tongue weights it can safely support. Make sure you have the proper hitch ball for the trailer. Incorrectly sized hitch balls are the #1 cause of trailer accidents. When hauling loads, 60% of the load on the trailer should be placed on the front half of the trailer, with a tongue weight of 10-15% of the total weight that’s loaded on the trailer. Ensure weight is evenly distributed on the left and right sides of the trailer. Straps are critical — broken or cheap straps can fail fast. Use ratchet straps for anything heavier than an average person and use more than one strap in case one comes loose. The working load of the strap should be more than the weight of what you’re hauling. Check your tires on both the vehicle and the trailer and make sure your lights work before you leave. Take spare bulbs and fuses with you. Check your brakes and make sure the breakaway cable is properly attached to your tow vehicle. Carry spare parts such as at least one trailer spare tire as well as extra wheel bearings and hubs.

g and damage your vehicle’s suspension. Check the hitch for the maximum trailer and maximum tongue weights it can safely support. Make sure you have the proper hitch ball for the trailer. Incorrectly sized hitch balls are the #1 cause of trailer accidents. When hauling loads, 60% of the load on the trailer should be placed on the front half of the trailer, with a tongue weight of 10-15% of the total weight that’s loaded on the trailer. Ensure weight is evenly distributed on the left and right sides of the trailer. Straps are critical — broken or cheap straps can fail fast. Use ratchet straps for anything heavier than an average person and use more than one strap in case one comes loose. The working load of the strap should be more than the weight of what you’re hauling. Check your tires on both the vehicle and the trailer and make sure your lights work before you leave. Take spare bulbs and fuses with you. Check your brakes and make sure the breakaway cable is properly attached to your tow vehicle. Carry spare parts such as at least one trailer spare tire as well as extra wheel bearings and hubs. signaling devices, emergency supplies and a first aid kit. Think about your footing and be alert to slippery areas. Watch for low hanging branches and take extra caution near cliffs, outcroppings, hills, and water edges. No matter how clear a stream looks, it’s likely to contain waterborne parasites & microorganisms, so pack your own water. Make sure your fires are always attended, cannot be spread laterally or vertically (used a grill or stone surface) and drown it with water to put it out. Embers buried deep in the pile can reignite later. Be cautious when using a propane stove. Tents should be flame retardant and far enough away from the campfire. Wear sunscreen, hats, sunglasses and drink plenty of water. Pack carbohydrate-energy bars, granola candy or fruit for instant energy on your hikes.

signaling devices, emergency supplies and a first aid kit. Think about your footing and be alert to slippery areas. Watch for low hanging branches and take extra caution near cliffs, outcroppings, hills, and water edges. No matter how clear a stream looks, it’s likely to contain waterborne parasites & microorganisms, so pack your own water. Make sure your fires are always attended, cannot be spread laterally or vertically (used a grill or stone surface) and drown it with water to put it out. Embers buried deep in the pile can reignite later. Be cautious when using a propane stove. Tents should be flame retardant and far enough away from the campfire. Wear sunscreen, hats, sunglasses and drink plenty of water. Pack carbohydrate-energy bars, granola candy or fruit for instant energy on your hikes.