OSHA’s Heat-Related Hazards National Emphasis Program

OSHA has issued a new NEP on heat-related hazards. In this article, we’ll discuss what it includes, which companies will be targeted and what OSHA inspectors will be looking for in their inspections.

What’s an NEP?

A National Emphasis Program, or NEP, is a temporary inspection emphasis based on a particular hazard that is typically are targeted to specific industry groups or NAICS codes where those hazards are most prevalent. Companies within those NAICS codes are randomly chosen for these inspections and others can be chosen because of past violations or certain circumstances. NEP inspections can be scheduled on their own, or companies can have them added to other OSHA inspections. For example, if someone at your facility has complained to OSHA about one hazard, OSHA can conduct an inspection on that complaint issue and then if they see something else onsite that’s covered by an NEP or a regional or local emphasis program, they can inspect for that too while they are there.

OSHA’s Heat Hazard NEP

The heat NEP covers both indoor and outdoor heat hazards. OSHA has had heat initiatives and heat awareness campaigns since 2021 and there has been debate in Congress about having a heat standard. This NEP is also a response to President Biden’s Executive Order to “Tackle the Climate Crisis at Home and Abroad.” The Secretary of Labor developed a Climate Action Plan with a goal of reducing heat-related illnesses and this is one of the ways they are going about that.

For purposes of measurement, OSHA considers a heat priority day to be one when the temperature is 80° F or higher. Programmed, targeted NEP inspections will be conducted on days when the National Weather Service has issued a heat advisory or warning, including a Heat Advisory, Heat Wave, Excessive Heat Outlook, Excessive Heat Watch and an Excessive Heat Warning.

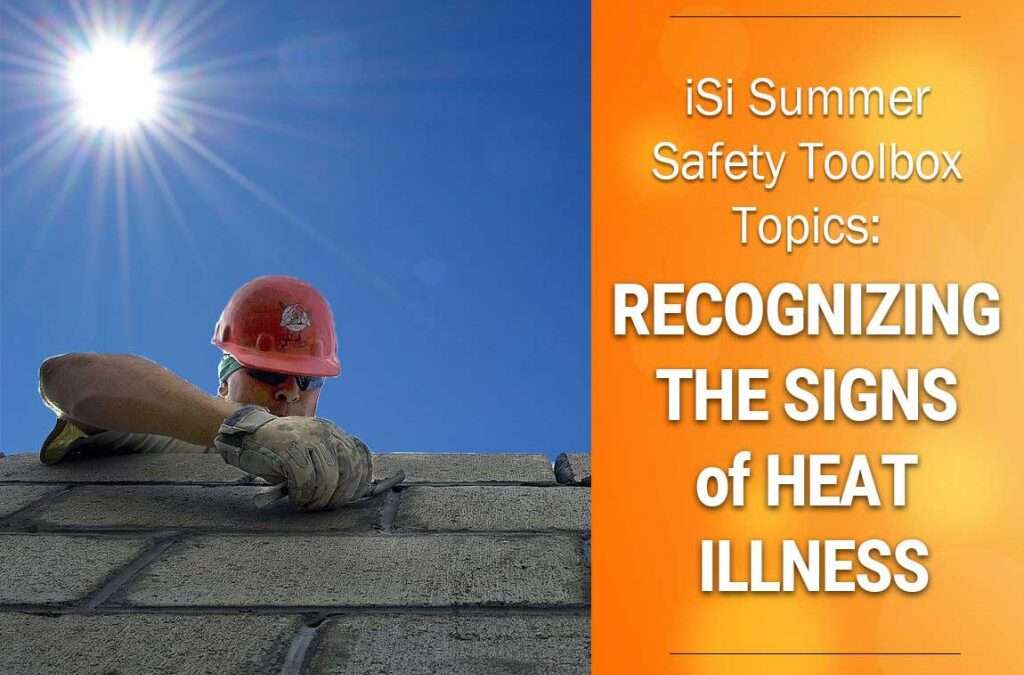

Which Companies Are Affected?

Of course, construction companies whose workers work out in the heat are affected. There are other non-construction companies who have been targeted as well as other industries who can be targeted at your OSHA Area Office’s discretion.

The list was too long to include in this article, but you can find a PDF copy of that here.

Farming is included on this list, however farms with 10 or less employees (not counting family members who work on the farm), who have stayed at or below that number for the past 12 months, and have not had any temporary labor camps in the past 12 months will be exempt from the NEP.

What Triggers an Inspection for this NEP?

You can end up on the inspection list for this in several different ways:

- You have a heat-illness related fatality, or have had a heat-illness related fatality that OSHA would like to follow up on;

- There’s an employee complaint about heat-illness hazards;

- Your company operates under one of the NAICS codes from the target list, you have been picked by OSHA’s random number generator and it’s a day when the National Weather Service has issued a heat alert;

- OSHA inspectors are already onsite, and they find a heat-related illness on OSHA 300 logs, observe hazardous heat conditions, an employee brings a heat-related hazard to the attention of the inspector, or it’s a heat priority day. Inspectors have been encouraged to ask about your heat-illness prevention program on heat priority days;

- OSHA previously cited you for a lack of a heat-illness prevention program and you still haven’t implemented one; or,

- Your company has been added to the list by your Area Office based on a referral by another agency such as the Wage and Hour Division, the EPA, or the U.S. Department of Agriculture, they saw a media report about your company which shows there may be a heat issue onsite, or from the Area Office consulting other reference directories to find potential companies to inspect.

What Will Inspectors Look For?

- Records Review – Inspectors will look at your OSHA 300 Logs and 301 Incident Reports for any entries indicating heat-related illnesses and will review any records of heat-related emergency room visits and/or ambulance transports even if there were no hospitalizations.

- Employee Interviews – Interviews of current employees, new employees and employees who were away from the worksite and recently returned to work will be conducted. Inspectors will be asking for symptoms of headache, dizziness, fainting, dehydration or other conditions that may indicate heat-related illness.

- Program Review – Next the inspector will look at your program. First, do you even have a written program? How do you monitor ambient temperatures and levels of work exertion at the worksite? Are you conducting calculations using a particular method suggested by NIOSH or ACGIH? Is there unlimited cool water that’s easily accessible and are you requiring additional hydration and rest breaks? Is there access to shade? What do you do to acclimatize new and returning workers? Do you have a buddy system for hot days? What kinds of administrative controls are used? Is work scheduled during cooler periods of the day? Do you have a screening program to identify health hazards? What does your training program contain?

- Documentation of Conditions – The inspector is to document any conditions they find relevant to heat hazards such as heat index, heat alerts, information they get from the OSHA-NIOSH Heat Safety Tool App and/or Wet Bulb Globe Temperature (WGBT) measurements. If they are there because of an incident, they’ll be looking at current conditions such as wind speed, relative humidity, dry bulb temperatures both at the workplace and in the shaded rest areas, WGBT, percentage of cloud cover and heat alerts.

- Observation of Heat-Related Hazards – Inspectors will be looking for potential sources of heat-related hazards such as exposure to sun, hot air or hot equipment. What PPE is being used, that is, it bulky and heavy or does is deflect heat? What tasks are being conducted and what’s the level of exertion being used to conduct those? How long are employees conducting these tasks and how long are they continuously conducting moderate to strenuous activities?

Which Standards Will Get Cited?

Most citations for these inspections will fall under the General Duty Clause. Other citations that could be tacked on, depending on the findings, could include:

- Recordkeeping – If the employee became unconscious or needed oxygen and it wasn’t recorded you could be cited here.

- Sanitation – Regulations in 1910.141 and 1926.51 specify your company is required to provide cool, potable water.

- Construction Safety Training and Education – Under 1926.20 and 1926.21, construction companies are required to have a safety and health program.

A New Standard on the Horizon

OSHA has a standard called Heat Illness Prevention in Outdoor and Indoor Work Settings already in the Prerule stage. They have passed the comment stages from their Advanced Notice of Proposed Rulemaking and are scheduled to next go to the Small Business Regulatory Enforcement Fairness study. In the meantime, there are several states with their own heat illness rules. In the state of California there are already requirements for outdoor workers, and the California legislature asked Cal-OSHA back in 2016 to come up with a standard for indoor workers. They have been working on that and are expected to have something in 2024. What’s caused the delay is the issue of determining the exact thresholds that can be feasible for all industries since so many indoor workplaces can be different.

What’s in a Heat Illness Prevention Program?

Stay tuned here to our blog for our upcoming article featuring OSHA’s suggestions for what should be included in your heat-illness prevention program.

Need Assistance?

iSi can help you with your heat-related programs, training, PPE evaluations and worker exposure monitoring. Contact us today!

Need Help?

Need an extra hand to get your safety issues covered? How about policies/programs developed or training conducted?